In the world of precision machining and metal fabrication, the integrity of your threads determines the integrity of your assembly. As we move into 2026, the demand for high-performance tooling has never been higher. Whether you are re-threading a stripped engine block or fabricating new industrial components, using the best heavy duty thread tap drill bits is non-negotiable.

This comprehensive guide reviews the top-performing taps and drill bits available this year. We focus on industrial-grade durability, chip ejection efficiency, and material hardness (HSS, Cobalt, and Carbide). From our top-rated ISO-529 standard taps to renowned market leaders like Irwin and Milwaukee, we cover the tools that professionals trust.

Table of Contents

- Buying Guide: How to Choose Industrial Taps

- Top 9 Heavy Duty Thread Taps of 2026

- 1. MSL002 Spiral Groove Tap (ISO-529)

- 2. MSL003 Screw Tip Tap (ISO-529)

- 3. Irwin Hanson High Carbon Steel Set

- 4. Drill America M42 Cobalt Taps

- 5. Milwaukee Shockwave Impact Duty

- 6. Greenlee Combination Drill/Tap

- 7. DeWalt Pilot Point Drill & Tap

- 8. Bosch M42 Cobalt Series

- 9. GearWrench Ratcheting Tap Set

- Summary Comparison Table

- Frequently Asked Questions

Buying Guide: How to Choose the Best Heavy Duty Thread Tap Drill Bits

Before selecting a tap, it is crucial to understand the specifications that define “heavy duty.” In 2026, standard carbon steel often fails to meet the rigors of modern alloys. Here is what you need to look for.

1. Material Composition

High-Speed Steel (HSS): The baseline for professional work. It withstands higher temperatures than carbon steel.

Cobalt (M35/M42): Essential for drilling and tapping hardened steel or stainless steel. Cobalt adds heat resistance and durability.

Carbide: The hardest option, typically used for production environments on cast iron or abrasive materials.

2. Flute Geometry

Spiral Groove (Flute): Best for blind holes (holes that do not go all the way through). The spiral design pulls chips up and out of the hole, preventing clogging.

Spiral Point (Gun Tap): Best for through holes. It pushes chips forward ahead of the tap.

Straight Flute: The most common general-purpose style, suitable for hand tapping.

3. Standards (ISO-529)

For industrial accuracy, look for compliance with standards like ISO-529. This international standard dictates the shank dimensions, thread tolerance, and overall length, ensuring your tap fits standard collets and holders perfectly.

Top 9 Best Heavy Duty Thread Tap Drill Bits 2026

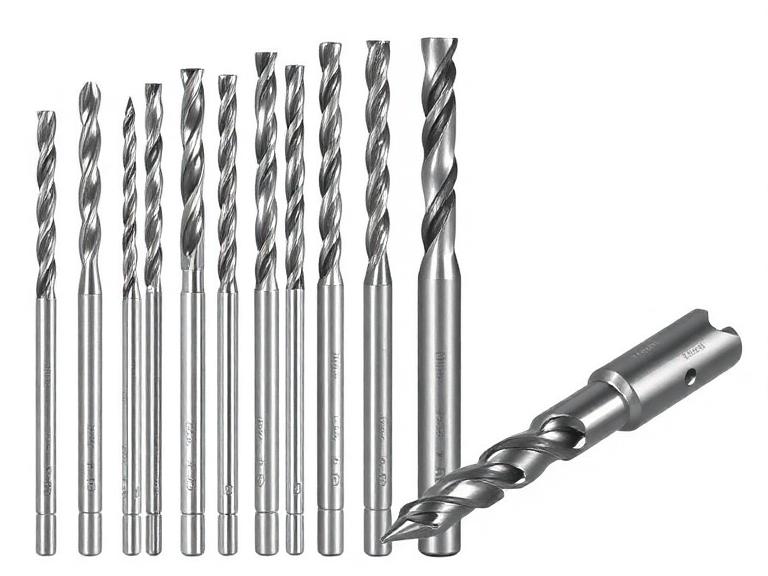

1. MSL002 Spiral Groove Tap With (ISO-529) National Industrial Standard (Rough Handle) Top Industrial Pick

For precision machining where chip evacuation is critical, the MSL002 stands out as a premier industrial solution. Designed specifically for blind hole applications, this tool prevents the common issue of chip packing at the bottom of the hole.

Key Features:

- Standard Compliance: Fully complies with the (ISO – 529) National Industrial Standard (Rough Handle) series, guaranteeing compatibility with professional CNC and manual milling setups.

- Efficient Chip Removal: The aggressive spiral groove geometry acts like an Archimedes screw, lifting swarf out of the cutting zone to ensure clean threads.

- Versatility: Available in a wide range of metric and imperial thread sizes to suit diverse fabrication needs.

Our Spiral groove tap ensures efficient chip removal with its spiral grooves. Available in various thread sizes, it offers precise and smooth threading, ideal for industrial machining needs.

2. MSL003 Screw Tip Tap With (ISO-529) National Industrial Standard (Rough Handle)

When speed and through-hole efficiency are the priority, the MSL003 Screw Tip Tap is the tool of choice. Often referred to as a “spiral point” or “gun tap” in the industry, this design is engineered to drive chips forward, allowing for higher tapping speeds.

Key Features:

- Specialized Tip Design: The angular grind on the tip shears chips and forces them ahead of the tool, keeping the flutes clear for coolant flow.

- ISO-529 Precision: Like its spiral counterpart, this model conforms strictly to ISO-529 standards, ensuring the shank and drive square fit perfectly in rigid tapping heads.

- Smooth Operation: It enables smooth and efficient threading, reducing torque load on the machine spindle.

Our Screw tip tap, conforming to (ISO – 529) National industrial standard (rough handle) series, features a specialized screw tip design. It enables smooth and efficient threading, with various thread sizes available, ideal for precise machining tasks in industrial applications.

3. Irwin Hanson High Carbon Steel Hex Drive Tap Set

Irwin is a household name in the threading world. Their “Hanson” line is synonymous with reliability. This set is particularly favored for automotive repair and maintenance (MRO) where cleaning up existing threads is a common task.

- Material: High Carbon Steel.

- Best For: Re-threading and cleaning rusted bolts.

- Feature: Precision-ground flutes provide easy chip clearance.

4. Drill America M42 Cobalt Taps

When you need to cut threads into stainless steel or titanium, standard HSS will burn up. Drill America’s M42 Cobalt series is the solution. Containing 8% cobalt, these taps possess high hot hardness, allowing them to cut tough alloys without losing their edge.

- Material: M42 Cobalt (8%).

- Best For: Hardened steel, stainless steel, and titanium.

- Feature: Gold oxide finish reduces friction and improves wear resistance.

5. Milwaukee Shockwave Impact Duty Drill & Tap Bits

The modern job site relies on impact drivers, and Milwaukee has adapted threading to match. The Shockwave series allows you to drill and tap in a single pass using your impact driver, saving massive amounts of time on electrical and HVAC installations.

- Shank: 1/4″ Hex specifically designed for impact drivers.

- Best For: Speed; drilling and tapping up to 1/4″ metal plate.

- Durability: Laser-hardened tip extends life under impact torque.

6. Greenlee Combination Drill/Tap Bits

Greenlee is the gold standard for electricians. Their combination bits are designed to drill, tap, and deburr in one operation. They are exceptionally high quality and are tuned specifically for the thread sizes most common in electrical panels and boxes.

- Material: High-Speed Steel.

- Function: Drill, Tap, and Countersink in one go.

- Best For: Electricians working with mild steel, aluminum, and brass.

7. DeWalt Pilot Point Drill & Tap Set

DeWalt’s entry into the heavy duty thread tap market features their patented Pilot Point tip. This design prevents the bit from “walking” on the metal surface upon start-up, ensuring the threaded hole is perfectly positioned every time.

- Coating: Titanium Nitride (TiN) for extended life.

- Design: One-piece construction prevents the bit from snapping at the shank.

- Best For: General construction and on-site metal fabrication.

8. Bosch M42 Cobalt Drill & Tap Series

Bosch brings German engineering to their M42 Cobalt line. These bits are engineered for high-heat applications. If you are drilling and tapping repetitively in a production environment, the heat resistance of the Bosch M42 alloy prevents premature failure.

- Heat Resistance: Withstands temperatures up to 1100°F.

- Web Design: Thick web provides extra stability for heavy feed rates.

- Best For: Cast iron and abrasive metal tapping.

9. GearWrench Ratcheting Tap and Die Set

While the focus here is often on the bit itself, the handle matters. GearWrench offers the best ratcheting “T” wrench system on the market. Their 5-degree ratcheting arc allows you to tap threads in tight engine compartments where a traditional handle cannot turn.

- System: Patented Twist Lock Guide System keeps dies centered.

- Best For: Automotive mechanics and tight spaces.

- Feature: Auto-locking feature allows for safe removal of tap adapters.

Summary Comparison Table

Compare the specifications of the best heavy duty thread tap drill bits below to find the right match for your workflow.

| Product Model | Material | Style | Best Application |

|---|---|---|---|

| MSL002 | Industrial HSS | Spiral Groove (ISO-529) | Blind holes, Industrial machining |

| MSL003 | Industrial HSS | Screw Tip / Spiral Point | Through holes, High speed |

| Drill America | M42 Cobalt | Standard/Spiral | Hardened Steel, Titanium |

| Milwaukee | Impact HSS | Combo Drill/Tap | Impact Drivers, Thin metal |

| Greenlee | HSS | Combo Drill/Tap | Electrical panels, Deburring |

| Bosch | M42 Cobalt | Jobber/Tap | Cast Iron, High Heat |

Frequently Asked Questions

Q: What is the difference between a spiral groove and a spiral point tap?

A: A Spiral Groove (MSL002) pulls chips out of the hole (like a drill bit), making it ideal for blind holes. A Spiral Point (MSL003) pushes chips forward, which is stronger and faster but only works for through holes where chips can exit the other side.

Q: Can I use these taps in a hand drill?

A: Yes, combination drill/tap bits (like Milwaukee or Greenlee) are designed for power drills. However, traditional ISO-529 taps (MSL series) are best used in a drill press, tapping arm, or with a hand wrench to ensure straightness.

Q: Why is M42 Cobalt better than HSS?

A: M42 Cobalt contains 8% cobalt, which allows the steel to remain hard at much higher temperatures. This is essential when cutting hard metals like stainless steel, which generate significant friction heat.

Q: What does ISO-529 mean?

A: ISO-529 is an international standard defining the dimensions of the tap, including the shank diameter and square drive size. Using ISO-standard tooling ensures that your taps fit correctly into standard industrial collets and holders.