In the world of mechanical assembly and precision engineering, damaged threads are a frequent and frustrating hurdle. Whether caused by cross-threading, corrosion, or over-torquing, the integrity of a fastener’s connection is vital for safety and performance. A common question arises among technicians and DIY enthusiasts alike: Can you use a tap to fix threads? The answer is nuanced, requiring an understanding of metalwork, tool geometry, and material fatigue.

While many reach for a standard cutting tap to “clean up” a damaged hole, there are significant differences between cutting new threads and repairing existing ones. Using the wrong tool or technique can result in stripped holes that are beyond repair. This comprehensive guide explores the mechanics of thread restoration and why high-quality tools are the foundation of any successful repair.

- Understanding the Role of a Tap in Threading

- Can You Use a Tap to Fix Threads? The Short Answer

- Cutting Taps vs. Thread Chasers: Key Differences

- How to Safely Repair Threads Using a Tap

- MisolGroup: Excellence in Thread Cutting Tools

- Material Considerations in Thread Restoration

- Common Mistakes to Avoid When Fixing Threads

- Summary Comparison Table

- Frequently Asked Questions

Understanding the Role of a Tap in Threading

A tap is a precision tool designed to cut the internal threads of a hole so it can receive a bolt or screw. Traditionally, these tools are used in manufacturing to create fresh threads in a pilot hole. They are made from extremely hard materials to ensure they can carve into steel, aluminum, or cast iron.

When considering the question, can you use a tap to fix threads, it is important to recognize that a standard tap is essentially a cutting tool. It has sharp flutes designed to remove metal. If you use a fresh cutting tap on damaged threads, it will likely cut away the remaining material rather than reshaping it, which can weaken the overall structural integrity of the joint.

Can You Use a Tap to Fix Threads? The Short Answer

Yes, you can use a tap to fix threads, but with a major caveat: a standard cutting tap should primarily be used to “clean” threads that are clogged with dirt, paint, or minor burrs. If the threads are severely flattened or cross-threaded, a cutting tap might remove too much metal, making the hole slightly oversized and the fit loose.

Professional mechanics often distinguish between “chasing” and “tapping.” If you are asking can you use a tap to fix threads on a critical engine component or a structural beam, the preferred method is often a thread chaser or a re-threading tap, which is designed to move metal back into place rather than cutting it away.

Cutting Taps vs. Thread Chasers: Key Differences

If you find yourself in a situation where a bolt won’t turn, you need to choose your tool wisely. A cutting tap has sharp edges and deep flutes to evacuate chips. A thread chaser (or re-threader) has blunter edges and is designed specifically for repair. The chaser follows the original thread path, smoothing out high spots and pushing displaced metal back into the valleys of the thread profile.

How to Safely Repair Threads Using a Tap

If you have determined that a tap is the right tool for your specific repair, following a disciplined process is essential to prevent permanent damage to the workpiece.

- Identification: Determine the exact thread pitch and diameter. Using a metric tap on an imperial hole will instantly ruin the part.

- Cleaning: Use compressed air or a wire brush to remove loose debris before inserting the tool.

- Lubrication: Never use a tap dry. Use a high-quality cutting oil or tapping fluid to reduce friction and heat.

- Alignment: Ensure the tap is perfectly perpendicular to the hole. Cross-threading a tap while trying to fix threads is a recipe for disaster.

- The “Back-Turn” Method: Turn the tap half a turn forward, then a quarter turn back. This breaks any chips and prevents the tool from binding.

MisolGroup: Excellence in Thread Cutting Tools

Since our founding in 2005, MisolGroup has established itself as a leading Chinese manufacturer of high-performance thread cutting tools, integrating R&D, production, and global sales into a seamless operation. When the question is can you use a tap to fix threads, the quality of the steel in that tap determines whether you succeed or break the tool inside the hole.

Advanced Manufacturing & Uncompromising Quality

Our commitment to excellence is embedded in our manufacturing process:

- Full In-House Production: We control the entire process with advanced CNC automation, vacuum heat treatment, and comprehensive testing facilities.

- Premium Materials: We use high-grade high-speed steels (HSS) like M35, DV3, and M2 to produce durable premium taps that ensure superior performance and longer tool life.

- R&D Expertise: Our strong R&D team, backed by nearly two decades of experience, focuses on innovating thread tool applications for the most demanding materials.

Engineered for Demanding Industries & Materials

Our threading tools are optimized to excel across a wide range of applications:

- Key Industries Served: Automotive, Aerospace, Defense, Electronics, and Mold & Die Manufacturing.

- Material Expertise: Effectively machining cast iron, carbon steel, stainless steel, and non-ferrous alloys.

A Partnership Built on Reliability and Integrity: Our strict, ISO-certified quality management system guarantees consistent reliability. We are recognized as a trustworthy, contract-compliant supplier committed to customer satisfaction.

Our Featured Products:

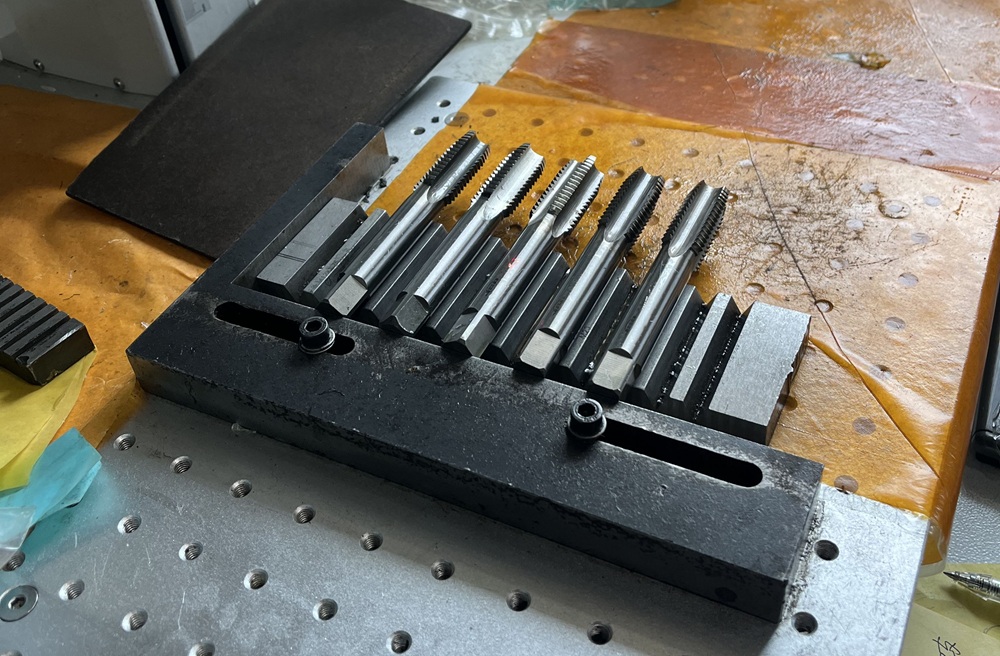

- (10S-529) standard series thread tap: The versatile choice for general workshop repairs and production.

- DIN371 German industrial standard thread tap: Built for high precision and European machinery specifications.

- JlS spiral groove tap series thread tap: Ideal for blind holes where chip evacuation is critical.

Explore the full MisolGroup catalog online for your thread repair needs.

Material Considerations in Thread Restoration

The success of using a tap to fix threads depends heavily on what the workpiece is made of. Soft metals like aluminum are very forgiving but also very easy to strip if you apply too much torque. Hardened steels require premium HSS-E or Cobalt taps (like the M35 series from MisolGroup) to prevent the tap from dulling or snapping.

When working with stainless steel, heat is your greatest enemy. Stainless tends to work-harden, meaning the more you struggle with the threads, the harder the metal becomes. In these cases, can you use a tap to fix threads? Yes, but only with a high-sulfur cutting oil and a very slow, steady hand.

Common Mistakes to Avoid When Fixing Threads

Repairing threads is a delicate operation. Avoid these frequent pitfalls:

- Using a T-handle for everything: While T-handles are common, they don’t always provide the best “feel” for the resistance of the metal. Sometimes a socket and ratchet (used with extreme care) can provide more leverage, though it increases the risk of snapping the tap.

- Ignoring the bottom of the hole: In a blind hole, debris accumulates at the bottom. If you don’t clean it out, the tap will bottom out on the debris, leading you to believe the threads are fixed when they are actually blocked.

- Reusing the damaged bolt: Even if you fix the internal threads, if the bolt threads are also stretched or nicked, it will just damage the hole again. Always use a new fastener.

Summary Comparison Table

| Tool Type | Primary Purpose | Best For… | Risk Level |

|---|---|---|---|

| Standard Cutting Tap | Creating new threads | Clearing debris or paint from holes | Moderate (Can remove too much metal) |

| Thread Chaser | Restoring damaged threads | Cross-threaded or flattened threads | Low (Reshapes rather than cuts) |

| Heli-Coil / Insert | Replacing ruined threads | Completely stripped holes | High (Requires drilling/re-tapping) |

| Spiral Flute Tap | Deep hole threading | Blind holes with restricted access | Moderate (Excellent chip removal) |

Frequently Asked Questions

1. How do I know if the threads are too damaged to fix with a tap?

If more than 25% of the thread material is missing or if the hole has been “wallered out” (made significantly larger than the bolt), a tap will not work. In these cases, you will need a thread insert like a Heli-Coil.

2. Can you use a tap to fix threads on a spark plug hole?

This is a specialized task. While a tap can be used, most professionals use a “Back-tap.” This tool expands once it is inside the cylinder and cuts its way out, ensuring the threads align perfectly with the undamaged interior section.

3. What is the difference between HSS and Cobalt taps for repair?

HSS (High-Speed Steel) is suitable for most general repairs. Cobalt (M35) taps are designed for higher heat resistance and harder materials like stainless steel. Using a Cobalt tap for thread repair ensures the tool stays sharp longer.

4. Should I turn the tap by hand or with a power tool?

For thread repair, always turn the tap by hand. Power tools remove the “feel” required to sense when a tap is about to bind or break. Manual control is the only way to ensure you are following the existing thread path.