In the world of precision machining and metalworking, choosing the right tool for threading applications is essential for achieving accurate and reliable results. Two common tools for creating threads are the thread chaser and the tap. While both are used for threading purposes, they have distinct differences that can impact the quality and efficiency of your work. In this article, we’ll explore the 6 key differences between a thread chaser and a tap.

1. Definition and Purpose

A thread chaser is a tool used primarily for repairing or chasing existing threads. It is commonly used in situations where a worn-out or damaged thread needs to be cleaned or re-shaped. Thread chasers are typically used in lathe operations, where the tool is applied to a rotating workpiece.

A tap, on the other hand, is used to cut new internal threads into a hole. It’s a cutting tool that’s inserted into a pre-drilled hole and is rotated to create precise, clean threads for bolts, screws, or other fasteners.

2. Application Areas

Thread chasers are mainly used for re-threading purposes. If a previously cut thread has become worn down or damaged, a thread chaser is used to restore its shape and function. They are often used in turning operations and are a great tool for lathe-based threading.

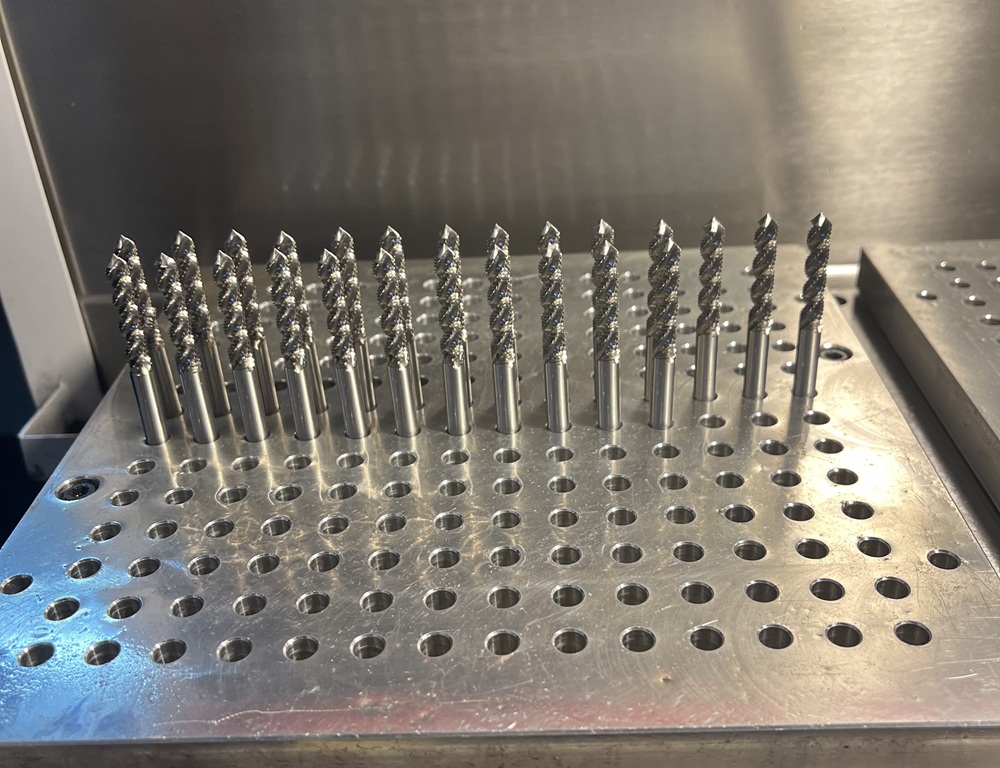

Taps are used for creating new internal threads in a hole. They are commonly used in drilling and tapping operations to prepare holes for screws or bolts. Taps are available in various types, including hand taps, machine taps, and spiral taps, depending on the application.

3. Material and Durability

Thread chasers are typically made of high-quality tool steels, but they are often used for less demanding tasks, such as chasing threads rather than cutting new ones. As such, they might not be as durable as taps in high-stress conditions.

Taps are made of tougher materials, often high-speed steel (HSS) or cobalt steel, which gives them greater durability and wear resistance when cutting new threads. Taps are designed to handle the stresses involved in creating threads from scratch, and they generally last longer than thread chasers under regular use.

4. Threading Process

Thread chasers operate by following the profile of an existing thread. They are typically used in manual lathe operations where the tool is guided by hand or machine to clean or chase the existing thread.

Taps create threads by cutting into the material as they rotate. This process is performed in a pre-drilled hole, and taps work by gradually removing material to form the internal thread needed for fasteners.

5. Types of Threads

Thread chasers are designed to match the existing thread profile, and they typically work with a variety of thread types such as UN, Metric, and BSW. They are often used for restoring damaged threads or adjusting threads to precise specifications.

Taps, however, are designed to create specific types of threads, such as coarse, fine, or extra-fine threads. They are used in the initial creation of internal threads and can produce threads with high precision.

6. Cost and Availability

Thread chasers tend to be less expensive than taps due to their simpler design and more limited applications. They are available in a variety of sizes and can be found from numerous manufacturers, including custom options for unique thread profiles.

Taps are generally more expensive than thread chasers because they are made from harder, more durable materials and are designed for more demanding tasks. They are widely available and come in many different forms for different thread sizes and materials.

Summary Table: Thread Chaser vs Tap

| Feature | Thread Chaser | Tap |

|---|---|---|

| Purpose | Used for re-threading or chasing existing threads | Used for cutting new internal threads |

| Material | Tool steel | High-speed steel (HSS), Cobalt |

| Durability | Less durable | More durable, designed for demanding tasks |

| Thread Type | Matches existing threads | Creates various thread types (coarse, fine, etc.) |

| Cost | Less expensive | More expensive |

Frequently Asked Questions

Can a thread chaser be used to create new threads?

No, thread chasers are only used to repair or chase existing threads. To create new threads, a tap should be used.

What are the most common industries that use taps?

Taps are commonly used in the automotive, aerospace, and electronics industries for creating internal threads in various materials such as metals, plastics, and composites.

How do I choose between a thread chaser and a tap?

If you need to repair or clean existing threads, a thread chaser is ideal. For creating new threads, especially in pre-drilled holes, a tap is the best option.

About MisolGroup

Since our founding in 2005, MisolGroup has established itself as a leading Chinese manufacturer of high-performance thread cutting tools. We specialize in R&D, production, and global sales of threading tools, providing top-quality solutions to industries such as automotive, aerospace, and electronics. Our products include:

We are committed to providing premium taps and threading solutions, backed by nearly two decades of experience in manufacturing and R&D.

References