This comprehensive guide explains how to choose a thread tap step by step. It covers tap types, materials, coatings, standards, hole conditions, and industry-specific requirements. By the end of this article, you will have a clear and professional understanding of how to choose a thread tap for any application.

Table of Contents

- Thread Tapping Basics

- Key Factors When Choosing a Thread Tap

- Choosing a Thread Tap by Material

- Types of Thread Taps Explained

- Thread Tap Standards and Sizes

- Tap Materials and Coatings

- MisolGroup Manufacturing Excellence

- Recommended Thread Tap Series

- Summary Table

- Frequently Asked Questions

- References

Thread Tapping Basics

Thread tapping is the machining process of cutting internal threads inside a pre-drilled hole. Understanding the fundamentals is the first step in learning how to choose a thread tap. A tap must match the hole size, material hardness, thread standard, and machining method.

Incorrect tap selection often results in broken tools, poor thread quality, excessive torque, or shortened tool life. This is why professional manufacturers invest time in learning how to choose a thread tap based on engineering principles rather than trial and error.

Key Factors When Choosing a Thread Tap

Workpiece Material

The workpiece material is the most important factor in how to choose a thread tap. Hard materials require tougher tap materials and optimized geometries, while softer materials benefit from sharper cutting edges and better chip evacuation.

Thread Type and Size

Metric, UNC, UNF, BSP, and special thread forms all require specific tap designs. When learning how to choose a thread tap, always confirm thread size, pitch, and tolerance class.

Hole Type

Through holes and blind holes demand different tap designs. This distinction plays a critical role in how to choose a thread tap for efficient chip evacuation.

Machine Type

Manual tapping, CNC tapping, and high-speed production all impose different requirements. High-speed CNC operations require taps with superior material quality and coatings.

Choosing a Thread Tap by Material

Knowing how to choose a thread tap for specific materials ensures stable cutting performance and extended tool life.

Carbon Steel

Carbon steel is widely used in mechanical components. Choosing a thread tap with HSS M2 or M35 material provides an excellent balance between toughness and wear resistance.

Stainless Steel

Stainless steel work-hardens easily, making it challenging. When deciding how to choose a thread tap for stainless steel, spiral flute taps with high-performance coatings are recommended.

Cast Iron

Cast iron produces powder-like chips. Straight flute taps are often effective, as chip evacuation is less critical.

Non-Ferrous Alloys

Aluminum and copper alloys benefit from sharp cutting edges and polished flutes. Understanding how to choose a thread tap for non-ferrous metals helps prevent material adhesion.

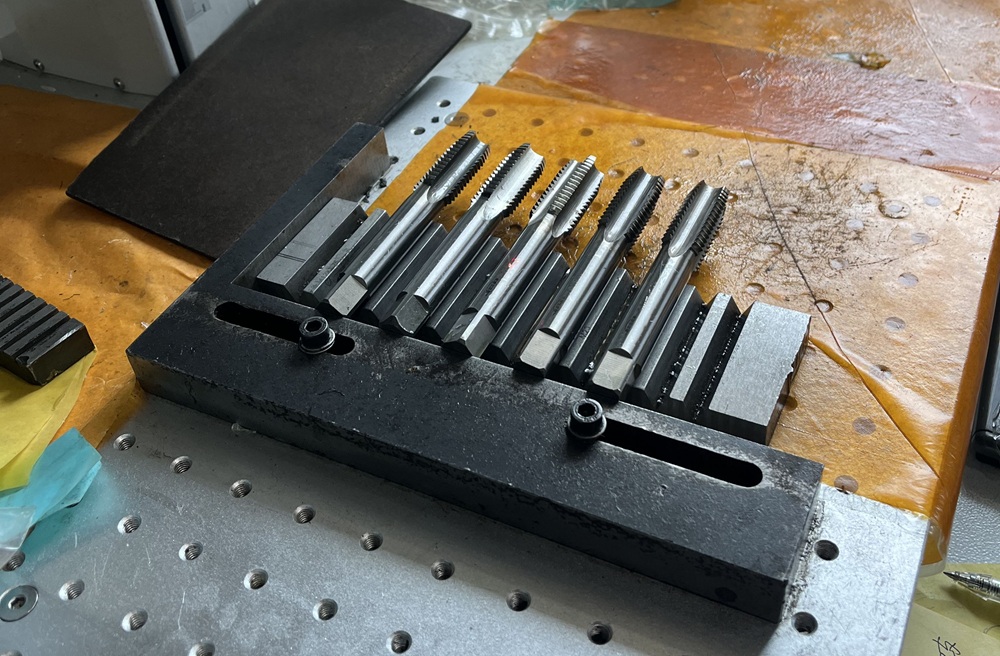

Types of Thread Taps Explained

Straight Flute Taps

Straight flute taps are versatile and suitable for general-purpose applications. They are commonly used in short-chipping materials.

Spiral Flute Taps

Spiral flute taps are ideal for blind holes. Their design pulls chips upward, reducing the risk of bottoming and breakage.

Spiral Point Taps

Spiral point taps push chips forward and are best for through holes. This design improves efficiency in high-speed CNC tapping.

Forming Taps

Forming taps create threads by cold forming rather than cutting. When learning how to choose a thread tap for ductile materials, forming taps are an excellent option.

Thread Tap Standards and Sizes

International standards play a critical role in how to choose a thread tap. Common standards include ISO, DIN, JIS, and ANSI.

Choosing the correct standard ensures thread compatibility, assembly reliability, and compliance with customer specifications.

Tap Materials and Coatings

High-Speed Steel Materials

High-quality taps are typically made from premium HSS materials such as M2, M35, and advanced alloys like DV3.

Surface Coatings

TiN, TiCN, and AlTiN coatings significantly improve wear resistance and reduce friction. Understanding coatings is essential when learning how to choose a thread tap for demanding applications.

MisolGroup Manufacturing Excellence

Since our founding in 2005, MisolGroup has established itself as a leading Chinese manufacturer of high-performance thread cutting tools, integrating R&D, production, and global sales into a seamless operation.

MisolGroup operates full in-house production with advanced CNC automation, vacuum heat treatment, and comprehensive testing facilities. This integrated manufacturing approach ensures consistent quality and performance.

Premium high-speed steels such as M35, DV3, and M2 are used to produce durable thread taps that deliver longer tool life and superior cutting performance.

Backed by nearly two decades of experience, MisolGroup’s R&D team continuously refines tap geometries to meet the demands of automotive, aerospace, defense, electronics, and mold manufacturing industries.

Recommended Thread Tap Series

10S-529 Standard Series

The 10S-529 standard series is designed for general-purpose threading across a wide range of materials. It provides stable performance and excellent cost efficiency.

DIN371 German Industrial Standard

DIN371 taps are engineered to meet strict German industrial standards, offering high precision and reliability for professional machining environments.

JIS Spiral Groove Tap Series

The JIS spiral groove tap series is optimized for blind hole applications, delivering smooth chip evacuation and consistent thread quality.

Summary Table: How to Choose a Thread Tap

| Factor | Recommendation |

|---|---|

| Material | Match tap material and geometry to workpiece hardness |

| Hole Type | Spiral flute for blind holes, spiral point for through holes |

| Standard | ISO, DIN, JIS, or ANSI based on application |

| Coating | Select coating for wear resistance and reduced friction |

| Machine | CNC taps for automated, high-speed operations |

Frequently Asked Questions

Why is tap selection so important?

Correct tap selection ensures thread accuracy, reduces breakage, and extends tool life.

How do I choose a thread tap for stainless steel?

Use spiral flute taps made from premium HSS with advanced coatings to handle work hardening.

Can one tap work for all materials?

No. Understanding how to choose a thread tap means matching the tap to each material and application.

References

- ISO Thread Standards Documentation

- DIN Thread Tapping Guidelines

- Industrial Machining Best Practices

- MisolGroup Technical Data and Manufacturing Insights