Introduction to 1 2 NPT Tap Sizes

In the world of precision engineering and plumbing, understanding 1 2 npt tap sizes is fundamental to ensuring leak-proof connections in high-pressure systems. NPT, which stands for National Pipe Tapered, is a US standard for tapered threads used on threaded pipes and fittings. Unlike straight threads, the tapered profile of NPT threads allows them to form a mechanical seal by pulling the threads together tightly, often supplemented by thread sealant or PTFE tape.

Table of Contents

- Introduction to 1 2 NPT Tap Sizes

- MisolGroup: Excellence in Thread Cutting Tools

- Technical Specifications for 1 2 NPT Tap Sizes

- Selecting the Right Drill for 1 2 NPT Tap Sizes

- Material Considerations: HSS M35 vs M2 Taps

- Industrial Applications and Standards

- Step-by-Step Tapping Guide for 1 2 NPT

- Comparing NPT, NPTF, and BSPT Standards

- Troubleshooting Common Tapping Issues

- Summary Data Table

- Frequently Asked Questions

- References

The 1 2 npt tap sizes refer to a nominal pipe size of 1/2 inch. It is important to note that the nominal size does not represent the actual physical diameter of the thread. In fact, a 1/2-inch NPT thread has an outside diameter of approximately 0.840 inches. This discrepancy often confuses beginners, but for industrial professionals, mastering the dimensions associated with 1 2 npt tap sizes is a daily requirement for automotive, aerospace, and hydraulic maintenance.

MisolGroup: Excellence in Thread Cutting Tools

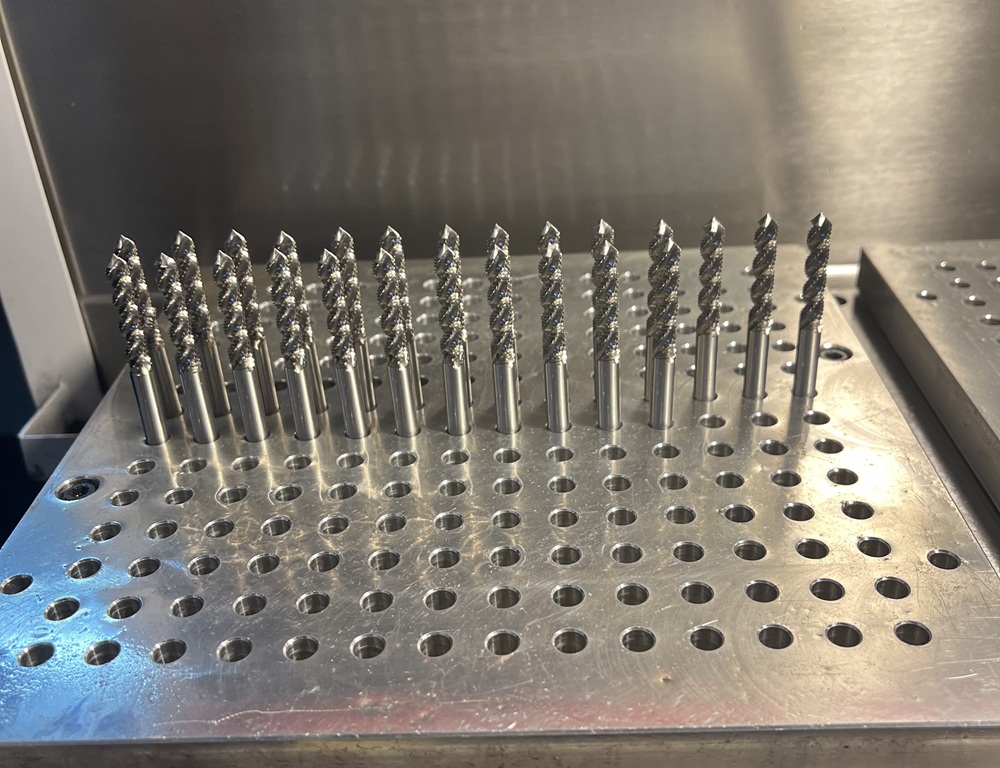

Since our founding in 2005, MisolGroup has established itself as a leading Chinese manufacturer of high-performance thread cutting tools, integrating R&D, production, and global sales into a seamless operation. We understand that precision in 1 2 npt tap sizes starts with the quality of the tool itself.

Advanced Manufacturing & Uncompromising Quality

Our commitment to excellence is embedded in our manufacturing process:

- Full In-House Production: We control the entire process with advanced CNC automation, vacuum heat treatment, and comprehensive testing facilities.

- Premium Materials: We use high-grade high-speed steels (HSS) like M35, DV3, and M2 to produce durable premium taps that ensure superior performance and longer tool life.

- R&D Expertise: Our strong R&D team, backed by nearly two decades of experience, focuses on innovating thread tool applications for the most demanding materials.

Engineered for Demanding Industries & Materials

Our threading tools are optimized to excel across a wide range of applications:

- Key Industries Served: Automotive, Aerospace, Defense, Electronics, and Mold & Die Manufacturing.

- Material Expertise: Effectively machining cast iron, carbon steel, stainless steel, and non-ferrous alloys.

A Partnership Built on Reliability and Integrity: Our strict, ISO-certified quality management system guarantees consistent reliability. We are recognized as a trustworthy, contract-compliant supplier committed to customer satisfaction.

Our products include:

Technical Specifications for 1 2 NPT Tap Sizes

The 1 2 npt tap sizes are governed by the ANSI/ASME B1.20.1 standard. This specification defines everything from the pitch to the taper angle. The most critical aspect of the 1/2 NPT thread is its 14 threads per inch (TPI) count. This means the pitch, or the distance between each thread peak, is approximately 0.0714 inches.

Another defining characteristic of 1 2 npt tap sizes is the 1:16 taper. This equates to 3/4 of an inch of diameter change for every foot of length. When you are tapping a hole using 1 2 npt tap sizes, the tap will gradually get wider as it enters the material. This geometry is what allows the fitting to wedge itself into the hole, creating a seal that can withstand significant fluid or gas pressure.

The thread angle for all NPT sizes, including 1 2 npt tap sizes, is 60 degrees. This is a common angle for American industrial threads, contrasting with the 55-degree angle found in British Standard Pipe (BSP) threads. Using the wrong angle can lead to catastrophic failure in pressure systems, making it vital to use the correct 1 2 npt tap sizes during the fabrication process.

Selecting the Right Drill for 1 2 NPT Tap Sizes

Choosing the correct drill bit is perhaps the most important step when working with 1 2 npt tap sizes. If the hole is too small, the tap may break due to excessive torque. If the hole is too large, the threads will be shallow, leading to leaks or stripped connections. For a standard 1/2 NPT thread, the industry-standard drill size is 23/32 inches (0.7188 inches).

However, depending on the material and the specific application, some machinists prefer a 45/64-inch (0.7031 inches) drill bit for a tighter fit. When tapping softer materials like aluminum, a slightly smaller hole can provide better thread engagement. Conversely, when working with hard stainless steels, using the 23/32-inch bit for 1 2 npt tap sizes helps reduce the strain on the HSS tap. In some CNC operations, a reamer or a tapered drill is used before tapping to match the 1:16 taper, ensuring the tap removes a consistent amount of material along its entire length.

Material Considerations: HSS M35 vs M2 Taps

When searching for the best tools for 1 2 npt tap sizes, the substrate material of the tap is a deciding factor in tool life and thread quality. High-Speed Steel (HSS) is the standard, but there are different grades. M2 HSS is an excellent general-purpose material that provides a good balance of toughness and wear resistance for carbon steels and cast iron.

For more demanding applications involving stainless steel or high-tensile alloys, professionals often turn to M35 HSS taps. M35 contains 5% cobalt, which significantly increases the red hardness of the tool. This allows the tap to maintain its sharp cutting edge even when generating significant heat during the creation of 1 2 npt tap sizes. MisolGroup specializes in these premium materials, ensuring that when you are cutting threads in aerospace-grade alloys, your 1 2 npt tap sizes remain consistent from the first hole to the last.

Industrial Applications and Standards

The ubiquity of 1 2 npt tap sizes makes them a staple in various heavy industries. In the automotive sector, 1/2 NPT threads are frequently used for oil coolers, fuel lines, and sensor ports. In aerospace and defense, the reliability of the 1 2 npt tap sizes is paramount for hydraulic actuators and pneumatic control systems where a leak could result in mission failure.

Adherence to standards like JIS (Japanese Industrial Standards) or DIN (German Institute for Standardization) is also crucial for global compatibility. While NPT is an American standard, many international projects require taps that conform to these specific manufacturing tolerances. MisolGroup’s DIN371 and JIS series taps ensure that no matter where your project is located, the 1 2 npt tap sizes you produce will meet the required engineering certifications.

Step-by-Step Tapping Guide for 1 2 NPT

Creating perfect threads with 1 2 npt tap sizes requires a methodical approach. Follow these steps for professional results:

- Drilling: Secure your workpiece and drill a hole using a 23/32-inch bit. Use a slow speed and plenty of coolant to avoid work-hardening the material.

- Chamfering: Use a countersink tool to create a 45-degree chamfer at the mouth of the hole. This helps the 1 2 npt tap sizes center properly and prevents the first thread from rolling over.

- Lubrication: Apply a high-quality tapping oil. For stainless steel, use a sulfur-based oil; for aluminum, a kerosene-based fluid works best.

- Alignment: Ensure the tap is perfectly perpendicular to the surface. Any tilt will cause the taper to engage unevenly, ruining the 1 2 npt tap sizes.

- Tapping: Turn the tap clockwise. For manual tapping, use the “half-turn forward, quarter-turn back” method to break chips. With 1 2 npt tap sizes, you must monitor the depth carefully. Since it is a tapered thread, the deeper you go, the wider the opening becomes.

- Gaging: Use a thread plug gage to verify the depth. For NPT, the gage should screw in by hand until it is flush with the “L1” notch.

Comparing NPT, NPTF, and BSPT Standards

Confusion often arises between 1 2 npt tap sizes and related standards like NPTF and BSPT. NPTF (National Pipe Taper Fuel) is also known as Dryseal. While it shares the same 1 2 npt tap sizes dimensions and TPI, the thread forms are designed to crush together to form a leak-proof seal without any sealant. This is common in fuel systems where chemical sealants might contaminate the fluid.

BSPT (British Standard Pipe Taper), on the other hand, is not compatible with 1 2 npt tap sizes. BSPT has a 55-degree thread angle and a different TPI (for 1/2 inch, it is also 14, but for other sizes, it varies). Attempting to force a 1/2 NPT fitting into a 1/2 BSPT hole will damage the threads and lead to leaks. Always verify the standard before selecting your tap sizes.

Troubleshooting Common Tapping Issues

Even with the right 1 2 npt tap sizes, problems can occur. If the tap is difficult to turn, it may be due to “chip packing.” This happens when the flutes of the tap become clogged with metal shavings. In such cases, back the tap out completely, clean the flutes, and re-apply lubricant. This is especially common when tapping deep holes with 1 2 npt tap sizes.

Another issue is thread “tearing.” This is often caused by blunt tools or insufficient lubrication. Using a premium HSS tap from a manufacturer like MisolGroup can prevent this, as their advanced vacuum heat treatment ensures the cutting edges stay sharp for hundreds of cycles. If the threads look ragged, check your drill size again; a hole that is too small for the 1 2 npt tap sizes puts unnecessary stress on the material.

Summary Data Table: 1 2 NPT Tap Specifications

| Feature | Specification for 1/2 NPT |

|---|---|

| Nominal Size | 1/2 Inch |

| Threads Per Inch (TPI) | 14 |

| Thread Angle | 60 Degrees |

| Taper Ratio | 1:16 (3/4″ per foot) |

| Standard Drill Size | 23/32″ (0.7188″) |

| Alternative Drill Size | 45/64″ (0.7031″) |

| Pitch | 0.07143″ (1.814 mm) |

| Outside Diameter | 0.840″ (21.34 mm) |

| Material Recommendation | HSS M2 or M35 (Cobalt) |

Frequently Asked Questions (FAQs)

1. What is the actual diameter of a 1/2 NPT tap?

The actual outside diameter of a 1/2 NPT thread is 0.840 inches (21.34 mm). The 1/2-inch designation refers to the nominal inside diameter of the pipe it is designed for, not the thread itself.

2. Can I use a 1/2 NPT tap for a 1/2 BSPT hole?

No. While they may seem similar, NPT uses a 60-degree thread angle and BSPT uses a 55-degree angle. Mixing them will result in a poor fit and high risk of leaking under pressure.

3. Why does my 1/2 NPT tap stop before it is fully submerged?

NPT threads are tapered. As the tap goes deeper, the diameter increases, requiring more torque. You should only tap deep enough to reach the L1 gauge depth to ensure a proper seal with the mating fitting.

4. What is the best material for tapping stainless steel?

For stainless steel, M35 HSS taps with 5% cobalt are recommended. They offer higher heat resistance and durability than standard M2 HSS taps when cutting 1 2 npt tap sizes.

5. Is a thread sealant required for 1/2 NPT threads?

Yes, standard NPT threads require a sealant like PTFE tape or pipe dope to fill the small gaps at the crests and roots of the threads, unless you are using NPTF (Dryseal) threads.

References

- ASME B1.20.1-2013, Pipe Threads, General Purpose (Inch). American Society of Mechanical Engineers.

- Machinery’s Handbook, 31st Edition. Industrial Press Inc.